A cleanroom is a room or space in which the level of particulate contamination is controlled within set levels. The construction, temperature, humidity, air flow patterns and pressure are controlled in such a way as to minimise the introduction, generation and retention of particles (such as dust) inside the room. These rooms are used commonly within the scientific research, medical, pharmaceutical and high technology manufacturing industries, where product/sample quality and employee well being are critical

External panels fire retardant massive impregnated high pressure Powder Coated G.I sheets, provided with protection film to avoid damage during the operational and commissioning phases.

Sandwiched triple glass panels by using 5mm toughened glass. Total thickness of the sandwiched glass panel will be suitable for the wall panels.

The spacer between the glasses is filled in with molecular sieves to absorb moisture.

The windows are installed flush with the wall and hermetically sealed with silicone sealant.

Windows, as specified, will be in the following standard sizes or as per the requirements of the client

Specially designed doors for flush application on movable walls, consisting of :

Cleanrooms operate under very strict internal air conditions that require HVAC systems to not only provide close-band temperature limits, but also humidity control and very high efficiency filtration. The HVAC systems are to delivery air change rates that are far in excess of normal building conditions, to ensure a low particle count for applications such a high quality product manufacture or scientific and medical research. HVAC cleanroom design within the electronics, aerospace and pharmaceutical industries.

HVAC usually refers to the mechanical system of the building that provides heating, ventilation and/or cooling within a building or a premise. This includes Air conditioners, Motor- blower assembly, Evaporative coil, Compressor, Compressor coil, Thermostats, Ductwork, Modules, Filters, Grilles, Diffusers and Dampers which help to distribute the conditioned air within a building. We follow a very stringent quality control systems and up to date guidelines, where we ensure every raw material received and every manufactured item is tested and approved as per the set quality norms. This ensures optimum performance of the equipment.

Air Clean Care Technology is a prominent service provider in the global market offering Cleanroom Validation Services.

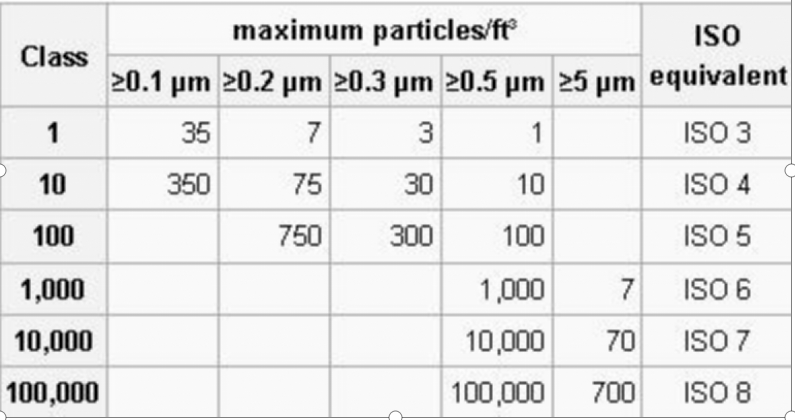

US FED STD 209E Cleanroom Standards

An Air Handling Unit (most of the times abbreviated to AHU), or Air Handler, is a central air conditioner station that handles the air that, usually, will be supplied into the buildings by the ventilation ductwork (connected to the AHU).

Handling the air means that the air will be delivered into the building spaces with thermo-hygrometric and IAQ (Indoor Air Quality) treatment. The accuracy of the treatment will depend from the specificity of each project (Pharmaceutical, Food, & Hospital industrial processes, etc).

This means, the Air Handling Unit treat the air by filtering with clean air, cooling and/or heating, humidifying and/or

Ducts are used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. The needed airflows include, for example, supply air, return air, and exhaust air.Ducts commonly also deliver ventilation air as part of the supply air.

Duct Wrap Insulation offers outstanding thermal properties that reduce unwanted heat loss or gain and condensation during system operation. This blanket-type insulation is used to insulate rectangular and round heating, ventilating and air conditioning ductwork.

Return air risers made out of same wall panel in the required sizes with stainless steel 304 (18G) (perforated on Turret Punch Press to avoid distortion) grille at the air inlet. The return air riser will also include 10µ Pre-filters.

Epoxy is a term that's come to represent a class of materials and the act of using those materials. ... When mixed together, the resin and hardener chemically react to form a rigid plastic material. The final material is strong, durable, resistant, and bonds extremely well to most base layers.

We do Conceptualization, Design, Execution, Testing, Qualification and Documentation (DQ,IQ, OQ & PQ) of Turnkey Cleanrooms, Biosafe and other Controlled Environs and provide training for operating personnel.